- Oxidation Industry solutions

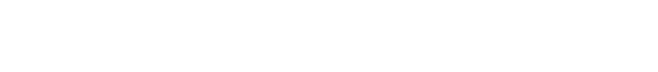

- DE wall panel oxidation regeneration process flow

- DE wall panel oxidation regeneration process

- Service History

- Open Mask Industry Solutions

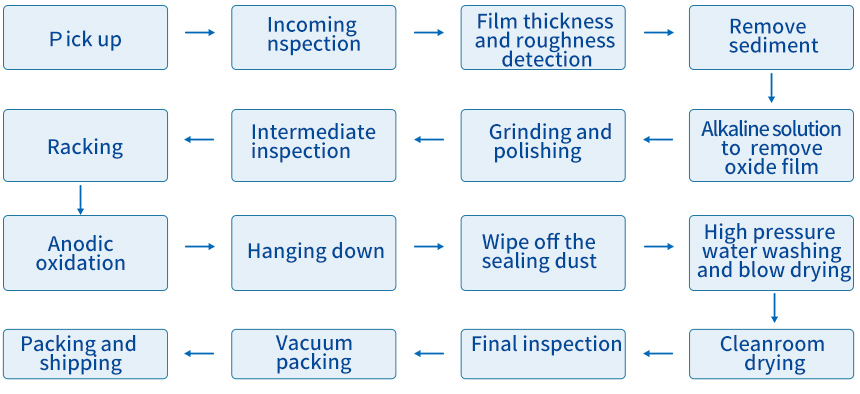

- Open Mask Operation process

- QC Flow Chart

- Open Mask Cleaning Process Flow

- Open Mask Cleaning specifications

- Cleaning specifications

- Semiconductor Industry Solutions

- Photovoltaic cleaning and regeneration process flow - carrier board

- Process flow of semiconductor component cleaning and regeneration

- Ceramic Melting Industry Solutions

- DE Ceramic Component Cleaning and Regeneration Process Flow

- DE Ceramic Component Cleaning Process

- Service History

- Surface treatment process flow of components

- Introduction to Ceramic Melting and Spraying

- Ceramic melting business

- Product Display (Optoelectronics)

- Product Display (Semiconductor)

- Product Display (Semiconductor ESC)

- Ceramic melting technology module

- Ceramic melt blown derivative process (stripping technology)

- Ceramic melt blown derivative process (new oxidation process)

- Surface treatment process flow of components

- Performance testing of oxidation new process performance indicators

- Ceramic melt blown derivative process (cleaning and regeneration process)

- Surface treatment process flow of components

- leaning and regeneration technology capability

- Special product (power on processing)

- Service History

- Cleaning industry Solutions

- PVD component cleaning and regeneration process flow

- Service History

- CF component cleaning and regeneration process flow

- IMP cleaning process flow

- Service History

- Process flow for cleaning and regenerating inner lining components

- Service History

- Quality control capability

- Cleaning and regeneration technology capability

- Advantages of advanced process precision cleaning

- Photovoltaic cleaning and regeneration process flow - carrier board

- CVD Industry Solutions

- CVD component cleaning and regeneration process flow - Diffuser

- CVD component cleaning and regeneration process flow - Baking Plate

- CVD component cleaning and regeneration process flow 1-Susceptor

- CVD component cleaning and regeneration process flow 2-Susceptor

- CVD component cleaning and regeneration process flow - Shadow Frame

- Core technology

- Service History

① Pick up

Receive cleaned and regenerated components from customers.

② Incoming inspection

Inspect the quality of incoming components and promptly provide feedback to customers on any quality defects and related photos.

③Film thickness and roughness detection

Inspect the dimensions, film thickness, and surface roughness of incoming components, analyze and evaluate them, and use the inspection data as the basis for developing anodizing production process parameters and confirming the quality inspection after anodizing.

④ Liquid wash

Soak in acetone solution and wipe with a white cloth to remove the deposited film on the surface of the component during production, in preparation for removing the oxide film.

⑤ Alkaline solution to remove oxide film

Remove the existing oxide film on the component by soaking it in NaOH solution.

⑥ Grinding and polishing

Use a pneumatic polishing machine to grind and polish the surface of the component to achieve the required roughness.

⑦ Intermediate inspection

The surface roughness after grinding is generally controlled withinRa=0.6±0.2um.

⑧ Racking

Use aluminum bars, aluminum fixing sleeves, and titanium screws for hanging.

⑨ Anodic oxidation

Perform electroplating, anodizing, coating and anodizing process on the components.

⑩ Hanging down

After drying the surface of the components, remove the aluminum fixing sleeve and titanium screws.

⑪ Wipe off the sealing dust

Use a white cleaning cloth or pneumatic polishing machine to remove the acne (white powder) generated during the sealing process of the components.

⑫ High pressure water washing and blow drying

⑬ Cleanroom drying

Use a large drying oven for final drying.

⑭ Final inspection

Perform final quality inspection and confirmation of the appearance, oxide film thickness, aperture, and surface roughness of the components.

Vacuum pack the components that have passed the final quality inspection.

⑮ Packing and shipping

Pack the components in bundles, boxes, and load them onto trucks for shipment.

|

Department |

Product |

Customer |

Generations |

Category |

|

Dry Etch |

Wall panel oxidation |

Hefei BOE(B3) |

G6 |

LCD |

|

Hefei Xinsheng(B5) |

G8.5 |

LCD |

||

|

Chengdu BOE(B7) |

G6 |

OLED |

||

|

ChongqingBOE(B8) |

G8.5 |

LCD |

||

|

HefeiBOE(B9) |

G10.5 |

LCD |

||

|

FuzhouBOE(B10) |

G8.5 |

LCD |

||

|

MianyangBOE(B11) |

G6 |

OLED |

||

|

WuhanBOE(B17) |

G10.5 |

LCD |

||

|

Nanjing panda |

G6 |

LCD |

||

|

AVIC |

G5 |

LCD |

||

|

Chengdu Tianma |

G4.5 |

LCD |

||

|

Shanghai Tianma |

G4.5 |

LCD |

||

|

Xiamen Tianma |

G6 |

LTPS |

||

|

G5.5 |

LTPS |

|||

|

Wuhan Tianma |

G4.5 |

LCD |

||

|

G6 |

OLED |

|||

|

Huaxing Optoelectronics T4 |

G6 |

OLED |

||

|

Guoxian Optoelectronics |

G5.5 |

OLED |

||

|

Shanghai Hehui |

G4.5 |

OLED |