- Oxidation Industry solutions

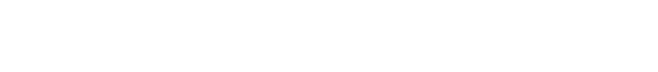

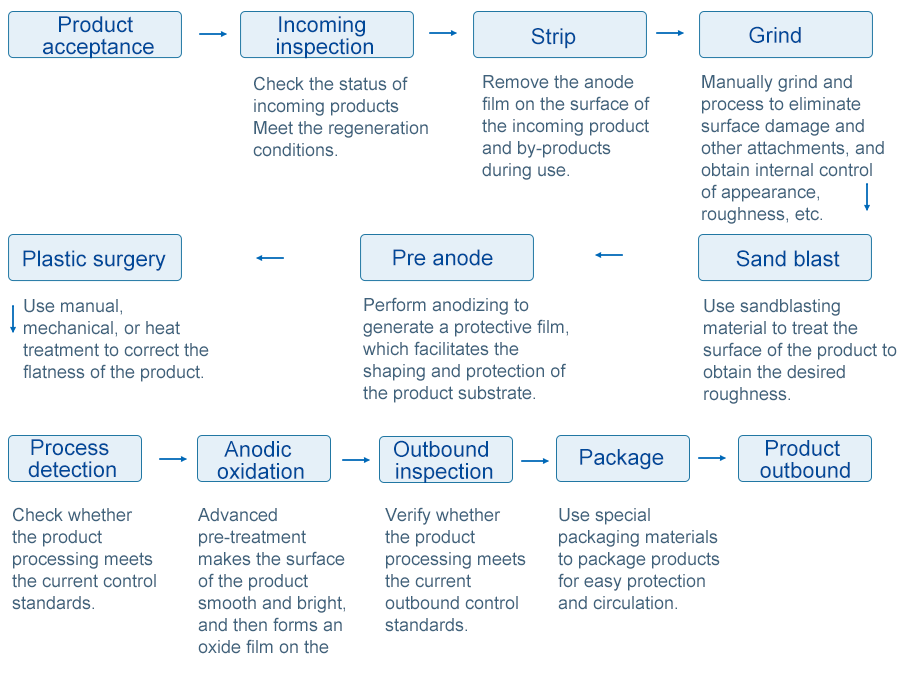

- DE wall panel oxidation regeneration process flow

- DE wall panel oxidation regeneration process

- Service History

- Open Mask Industry Solutions

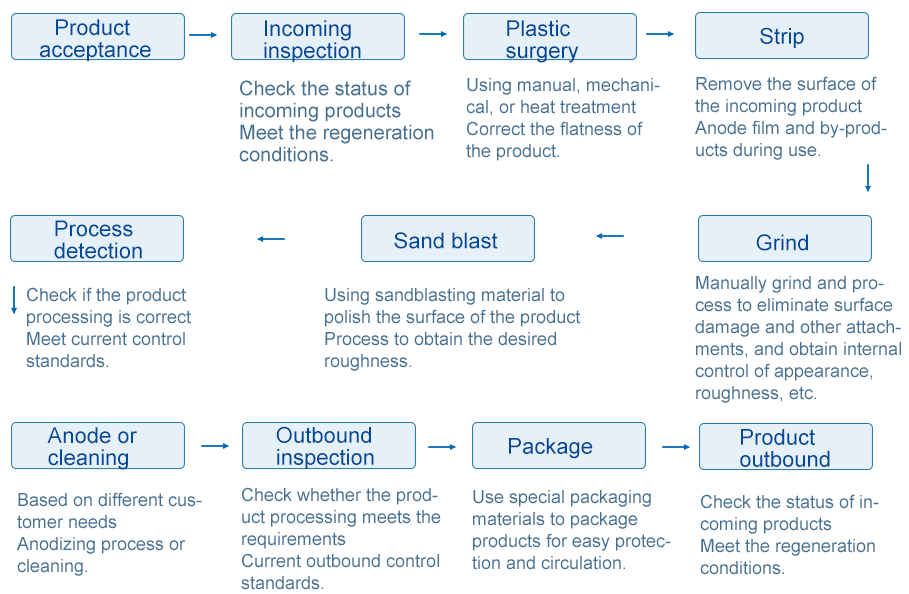

- Open Mask Operation process

- QC Flow Chart

- Open Mask Cleaning Process Flow

- Open Mask Cleaning specifications

- Cleaning specifications

- Semiconductor Industry Solutions

- Photovoltaic cleaning and regeneration process flow - carrier board

- Process flow of semiconductor component cleaning and regeneration

- Ceramic Melting Industry Solutions

- DE Ceramic Component Cleaning and Regeneration Process Flow

- DE Ceramic Component Cleaning Process

- Service History

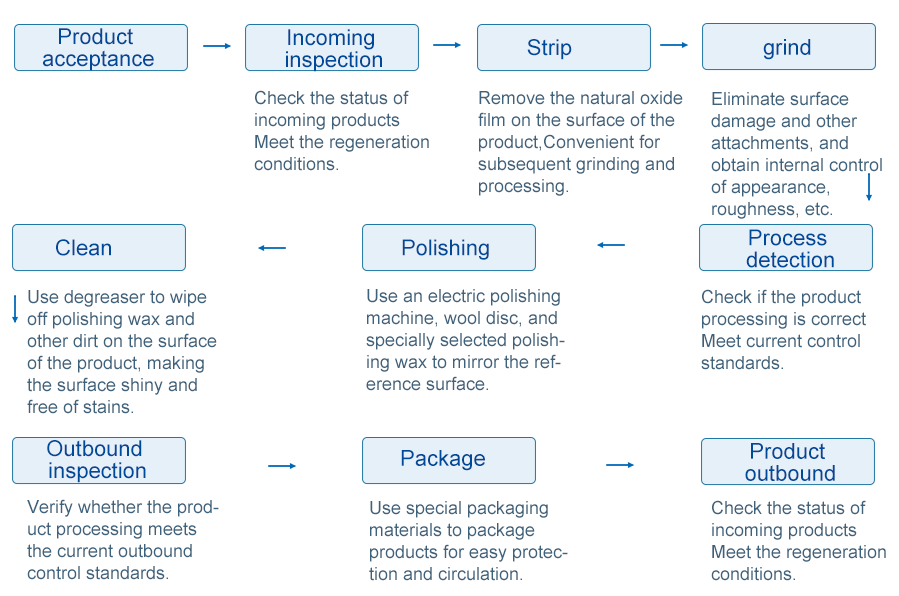

- Surface treatment process flow of components

- Introduction to Ceramic Melting and Spraying

- Ceramic melting business

- Product Display (Optoelectronics)

- Product Display (Semiconductor)

- Product Display (Semiconductor ESC)

- Ceramic melting technology module

- Ceramic melt blown derivative process (stripping technology)

- Ceramic melt blown derivative process (new oxidation process)

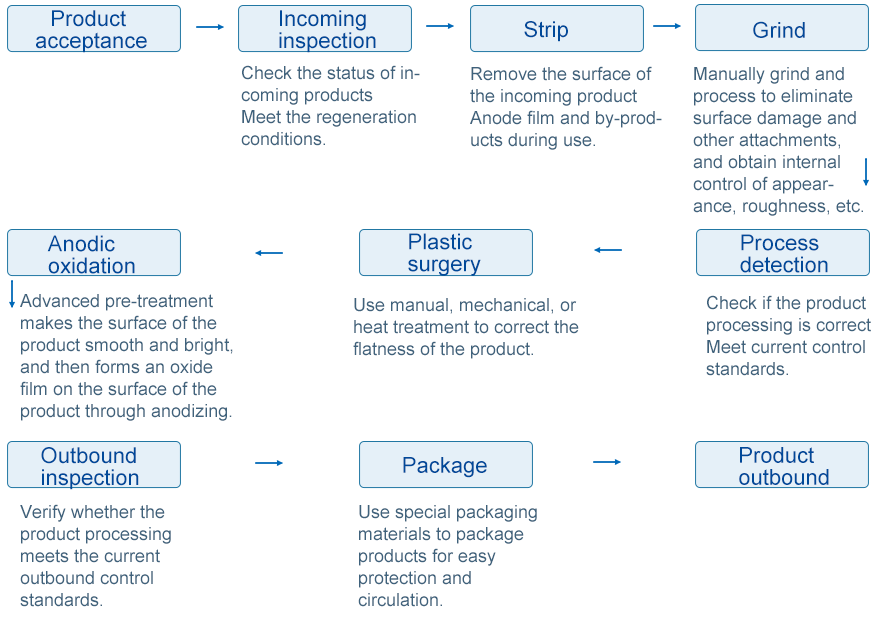

- Surface treatment process flow of components

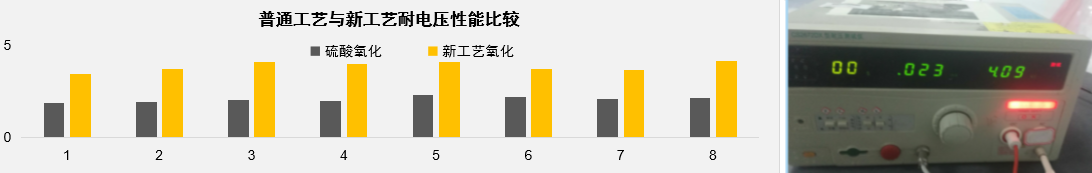

- Performance testing of oxidation new process performance indicators

- Ceramic melt blown derivative process (cleaning and regeneration process)

- Surface treatment process flow of components

- leaning and regeneration technology capability

- Special product (power on processing)

- Service History

- Cleaning industry Solutions

- PVD component cleaning and regeneration process flow

- Service History

- CF component cleaning and regeneration process flow

- IMP cleaning process flow

- Service History

- Process flow for cleaning and regenerating inner lining components

- Service History

- Quality control capability

- Cleaning and regeneration technology capability

- Advantages of advanced process precision cleaning

- Photovoltaic cleaning and regeneration process flow - carrier board

- CVD Industry Solutions

- CVD component cleaning and regeneration process flow - Diffuser

- CVD component cleaning and regeneration process flow - Baking Plate

- CVD component cleaning and regeneration process flow 1-Susceptor

- CVD component cleaning and regeneration process flow 2-Susceptor

- CVD component cleaning and regeneration process flow - Shadow Frame

- Core technology

- Service History

TQ process

Stable Anodizing Treatment Technology under High Temperature Process → Enhanced Durability on CVD Parts Film (Particle, Arcing)

Applicable products: Susceptor, Diffuser, Shadow Frame, etc

CLEANINGHole

Cleaning technology

- Internal cleaning and suppression of hole enlargement in Hole.。

TQ process

TQ coating=better corrosion resistance

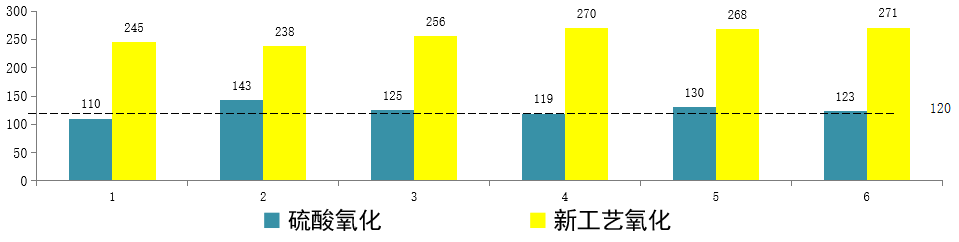

Anodizing technology for improving etching resistance → strengthening the corrosion resistance of oxide film

Applicable products: DIFF SUS S/F, etc

Corrosion resistance test

According to the standard LAM experimental method, Porous conducts a Bubble Test on the product's resistance to HCl, with a judgment criterion of greater than 120 minutes

Heat treatment and DOME formation technology

Having a large heat treatment furnace.

Mastering traditional thermoforming techniques and anodizing before shaping better protects the surface of the product.

Develop new shaping techniques, perform bowl shaped shaping before sandblasting, and after sandblasting, due to the splashing of glass beads, the SUS will become the umbrella shape we want. Greatly improve delivery time.

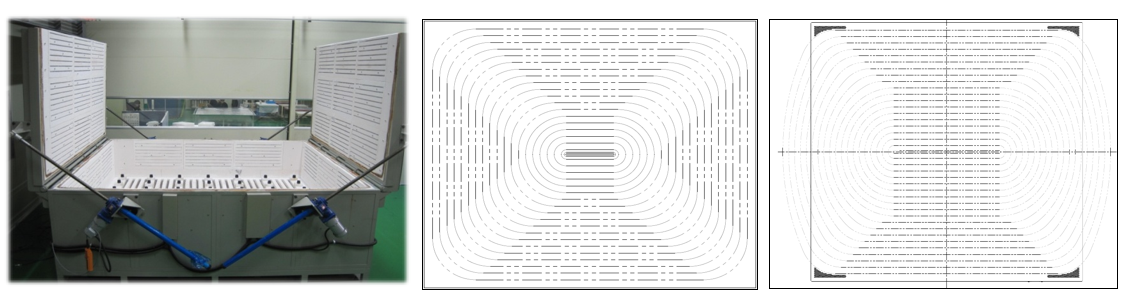

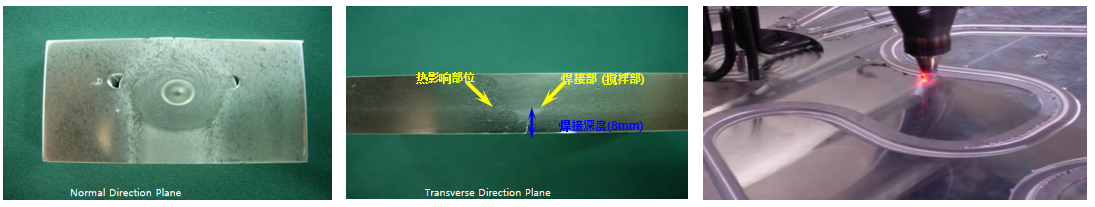

Welding technology

Susceptor Welding Technology: FSW.

-The melting process without materials results in no change in material properties.

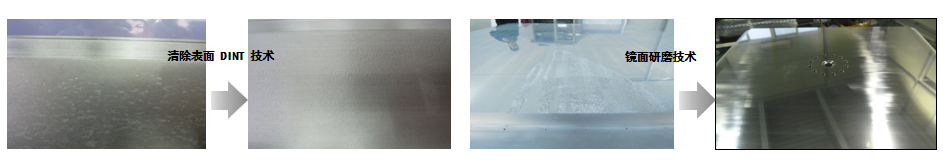

Polishing

Having effective removal of surface Dint, Arcing, Burr's accumulated experience. (Ensuring the competitiveness of repaired products).

Mirror polishing (for backing plate) technology

-Mirror treatment technology for removing corrosion and cleaning the surface of the backing plate. (GU>600).

|

Department |

Product |

Customer |

Generations |

Category |

|

CVD |

Shadow frame |

Shanghai Tianma |

G4.5 |

LCD |

|

Wuhan Tianma |

G4.5 |

LCD |

||

|

Chengdu Tianma |

G4.5 |

LCD |

||

|

Ivo |

G5 |

LCD |

||

|

Diffuse frame |

Chengdu Tianma |

G4.5 |

LCD |

|

|

Wuhan Tianma |

G4.5 |

LCD |

||

|

Shanghai Tianma |

G4.5 |

LCD |

||

|

Ivo |

G5 |

LCD |

||

|

AVIC Optoelectronics |

G 5 |

LCD |

||

|

Process kits/liner |

Shanghai Tianma |

G4.5 |

LCD |

|

|

Wuhan Tianma |

G4.5 |

LCD |

||

|

Chengdu Tianma |

G4.5 |

LCD |

||

|

Huaxing Optoelectronics Experimental Line |

G4.5 |

OLED |

||

|

AVIC Optoelectronics |

G 5 |

LCD |

||

|

Ivo |

G 5 |

LCD |

||

|

Electrode frame |

Au optronics |

G 6 |

LTPS |

|

|

CSOT |

G 6 |

LTPS |

|

Department |

Product |

Customer |

Generations |

Category |

|

CVD |

Backing plate |

Shanghai Tianma |

G4.5 |

LCD |

|

AVIC Optoelectronics |

G 5 |

LCD |

||

|

Xiamen Tianma |

G5.5 |

LCD |

||

|

Chuzhou Huike |

G8.6 |

LCD |

||

|

Chongqing Huike |

G8.6 |

LCD |

||

|

CSOT |

G 6 |

LTPS |

||

|

Backboard |

Au optronics |

G 6 |

LTPS |

|

|

Xiamen Tianma |

G5.5 |

LTPS |

||

|

Ceramics(shadow frame) |

Shanghai Tianma |

G4.5 |

LCD |

|

|

Wuhan Tianma |

G4.5 |

LCD |

||

|

Chengdu Tianma |

G4.5 |

LCD |

||

|

AVIC Optoelectronics |

G 5 |

LCD |

||

|

Au optronics |

G 6 |

LTPS |

||

|

CSOT |

G 6 |

LTPS |

||

|

Wuhan Tianma |

G 6 |

OLED |

|

Department |

Product |

Customer |

Generations |

Category |

|

CVD |

Susceptor |

AVIC Optoelectronics |

G5 |

LCD |

|

Ivo |

G5 |

LCD |

||

|

Wuhan Tianma |

G4.5 |

LCD |

||

|

Chongqing Huike |

G8.5 |

LCD |

||

|

Diffuser |

AVIC Optoelectronics |

G5 |

LCD |

|

|

Ivo |

G5 |

LCD |

||

|

Wuhan Tianma |

G4.5 |

LCD |

||

|

G 6 |

OLED |

|||

|

Guoxian Optoelectronics |

G5.5 |

OLED |

||

|

Chongqing Huike |

G8.5 |

LCD |

||

|

Ceramic processing |

Shanghai Tianma |

G4.5 |

LCD |

|

|

Wuhan Tianma |

G4.5 |

LCD |

||

|

Chengdu Tianma |

G4.5 |

LCD |

||

|

AVIC Optoelectronics |

G 5 |

LCD |

||

|

Ivo |

G 5 |

LCD |