- Oxidation Industry solutions

- DE wall panel oxidation regeneration process flow

- DE wall panel oxidation regeneration process

- Service History

- Open Mask Industry Solutions

- Open Mask Operation process

- QC Flow Chart

- Open Mask Cleaning Process Flow

- Open Mask Cleaning specifications

- Cleaning specifications

- Semiconductor Industry Solutions

- Photovoltaic cleaning and regeneration process flow - carrier board

- Process flow of semiconductor component cleaning and regeneration

- Ceramic Melting Industry Solutions

- DE Ceramic Component Cleaning and Regeneration Process Flow

- DE Ceramic Component Cleaning Process

- Service History

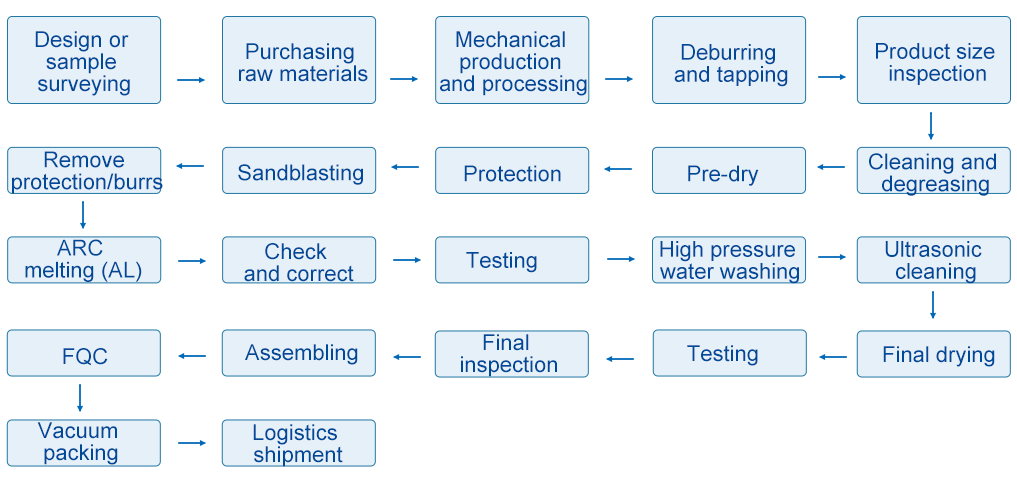

- Surface treatment process flow of components

- Introduction to Ceramic Melting and Spraying

- Ceramic melting business

- Product Display (Optoelectronics)

- Product Display (Semiconductor)

- Product Display (Semiconductor ESC)

- Ceramic melting technology module

- Ceramic melt blown derivative process (stripping technology)

- Ceramic melt blown derivative process (new oxidation process)

- Surface treatment process flow of components

- Performance testing of oxidation new process performance indicators

- Ceramic melt blown derivative process (cleaning and regeneration process)

- Surface treatment process flow of components

- leaning and regeneration technology capability

- Special product (power on processing)

- Service History

- Cleaning industry Solutions

- PVD component cleaning and regeneration process flow

- Service History

- CF component cleaning and regeneration process flow

- IMP cleaning process flow

- Service History

- Process flow for cleaning and regenerating inner lining components

- Service History

- Quality control capability

- Cleaning and regeneration technology capability

- Advantages of advanced process precision cleaning

- Photovoltaic cleaning and regeneration process flow - carrier board

- CVD Industry Solutions

- CVD component cleaning and regeneration process flow - Diffuser

- CVD component cleaning and regeneration process flow - Baking Plate

- CVD component cleaning and regeneration process flow 1-Susceptor

- CVD component cleaning and regeneration process flow 2-Susceptor

- CVD component cleaning and regeneration process flow - Shadow Frame

- Core technology

- Service History

①Design or sample surveying

Design products according to customer needs or provide samples, and process them according to sample surveying and mapping.

②Purchasing raw materials

Purchase imported high-precision flatness aluminum cutting plates AL5052, AL5083, AL6061, etc. according to customer needs.

③Mechanical production and processing

Select appropriate processing equipment for processing based on product size and technical requirements. Can be processed

Materials include aluminum, titanium, stainless steel, ceramics, quartz, and engineering plastics (Peek, PBI, etc.).

④Deburring and tapping

After product processing, some parts of the product have residual burrs and sharp edges, which need to be removed and undergo preliminary appearance inspection. Some products have threads and require tapping with a tapping machine as required.

⑤Product size inspection

Perform dimensional and visual inspections on the processed products.

⑥Cleaning and degreasing

The oil stains on the surface of the components are removed in the degreasing tank.

⑦Pre-dry

After soaking in pure water, pre drying is carried out to remove surface moisture, which is beneficial for the next process operation.

⑧Protect

Parts that do not require sandblasting should be protected with tape or fixtures.

⑨Sand blast

Under a certain process pressure, sandblasting is performed on the components to achieve the required roughness standard for film deposition.

⑩Remove protection/burrs/inspect and correct

After sandblasting is completed, remove the protective fixtures and tape, remove burrs at the edges of the sandblasting, and correct any deformations or dimensional defects.

The parts are placed on a marble platform and the warpage is measured using a feeler gauge. If it is not within the standard range, it should be corrected to ensure that the flatness is qualified. The measurement data should be recorded on the checklist.

⑪Detection

Measure the components with measuring tools according to the items specified in the checklist, and record the results on the checklist.

⑫High pressure water washing

Under certain process pressure, perform rough cleaning on sandblasted parts to remove surface particles.

⑬ARC melting

⑭Data detection

⑮High pressure water washing

According to the process parameters specified in the process flow sheet, set the parameters of the ARC meltblown machine and perform the melting operation. After the operation is completed, evaluate and measure the roughness of the melted coating to ensure that the measurement data meets the standard requirements. Then, proceed to the next process for high-pressure water washing to remove surface dust.

⑯Final drying

Dry according to the process requirements

⑰Final inspection

Conduct a visual inspection to check for any appearance defects, and conduct relevant dimensional data checks based on the inspection checklist.

⑱Assembling

⑲QC inspection

Assemble components according to standard drawings, paying attention to the directionality of the components during assembly. After the assembly is completed, FQC will inspect and confirm the appearance and dimensional data.

⑳Vacuum packing

Inner white and outer green vacuum packaging (two-layer).

㉑OQC/Packing and Shipping

According to the customer category, equipment, film quality, etc. on the process flow sheet, cushion material air cushion film is bundled and packed into boxes.

OQC prepares inspection reports and lists, and ships after packing is completed.

|

Department |

Product |

Customer |

Generations |

Category |

|

PVD |

MASK |

Shanghai Tianma |

G4.5 |

LCD |

|

Wuhan Tianma |

G4.5/G6 |

LCD/OLED |

||

|

Chengdu Tianma |

G4.5 |

LCD |

||

|

Xiamen Tianma |

G5.5/G6 |

LTPS |

||

|

AVIC |

G5 |

LCD |

||

|

Soaring dragon |

G5 |

LCD |

||

|

Nanjing Panda |

G6 |

LCD |

||

|

Guoxian Optoelectronics |

G5.5 |

OLED |

||

|

Soaking plate |

Shanghai Tianma |

G4.5 |

LCD |

|

|

Wuhan Tianma |

G4.5/G6 |

LCD/OLED |

||

|

Chengdu Tianma |

G4.5 |

LCD |

||

|

Xiamen Tianma |

G5.5 |

LTPS |

||

|

AVIC |

G5 |

LCD |

||

|

Soaring dragon |

G5 |

LCD |

||

|

Guoxian Optoelectronics |

G5.5 |

OLED |

|

Department |

Product |

Customer |

Product classification |

Generations |

category |

|

Dry Etch |

Wall panel processing |

Wuhan Tianma G6 |

TEL wall panel |

G6 |

OLED |

|

Wuhan Huaxing T4 |

TEL/ICD/YAC wall panel |

G6 |

OLED |

||

|

Wuhan Huaxing T3 |

TEL/ICD/YAC wall panel |

G6 |

LTPS |

||

|

Hefei BOE B5 |

TEL/ADP oxidation plate |

G8.5 |

LCD |

||

|

Chuzhou Huike |

IPS oxidation plate |

G8.6 |

LCD |

||

|

Xiamen Tianma T18 |

IPS oxidation plate |

G6 |

OLED |

||

|

Wuhan Tianma G4.5 |

TEL wall panel |

G4.5 |

LCD |

||

|

AVIC |

TEL oxidation plate |

G5 |

LCD |

||

|

Xiamen Tianma G6 |

TEL wall panel |

G6 |

LTPS |

||

|

Zhengzhou Huarui |

TEL wall panel |

G5 |

LCD |

||

|

Hefei BOE B9 |

IPS wall panel |

G10.5 |

LCD |

||

|

Chengdu Tianma |

TEL wall panel |

G4.5 |

LCD |

||

|

Mianyang BOE B11 |

TEL wall panel |

G6 |

OLED |

||

|

Chengdu BOE B7 |

TEL wall panel |

G6 |

OLED |

|

Department |

Product |

Customer |

Product classification |

Generations |

category |

|

Dry Etch |

Ceramic processing |

武汉华星T4 |

TEL/ICD/YAC Ceramics |

G6 |

OLED |

|

Wuhan Huaxing T3 |

TEL/ICD/YAC Ceramics |

G6 |

LTPS |

||

|

Wuhan Tianma G4.5 |

TEL Ceramics |

G4.5 |

LCD |

||

|

AVIC |

TEL Ceramics |

G6 |

LCD |

||

|

Xiamen Tianma G6 |

TEL Ceramics |

G6 |

LTPS |

||

|

Zhengzhou Huarui |

TEL Ceramics |

G6 |

LCD |

||

|

Wuhan Tianma G6 |

TEL Ceramics |

G6 |

OLED |

|

Department |

Product |

Customer |

Generations |

category |

|

CVD |

Shadow Frame process |

Shanghai/Wuhan/Chengdu Tianma |

G4.5 |

LCD |

|

AVIC Optoelectronics |

G5 |

LCD |

||

|

Ivo |

G5 |

LCD |

||

|

Process kits process |

Shanghai/Wuhan/Chengdu Tianma |

G4.5 |

LCD |

|

|

AVIC Optoelectronics |

G5 |

LCD |

||

|

Ceramic processing |

Shanghai/Wuhan/Chengdu Tianma |

G4.5 |

LCD |

|

|

AVIC Optoelectronics |

G5 |

LCD |

||

|

Ivo |

G5 |

LCD |

||

|

CF |

Carrier/Tray/Cover process |

Wuhan Tianma Carrier/Cover |

G4.5 |

LCD |

|

Nanjing Panda Tray/Cover |

G6 |

LCD |

||

|

Hefei BOE (B3) Carrier |

G6 |

LCD |

||

|

Xiamen Tianma Carrier/Cover |

G5.5 |

LCD |