- Oxidation Industry solutions

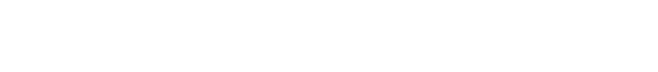

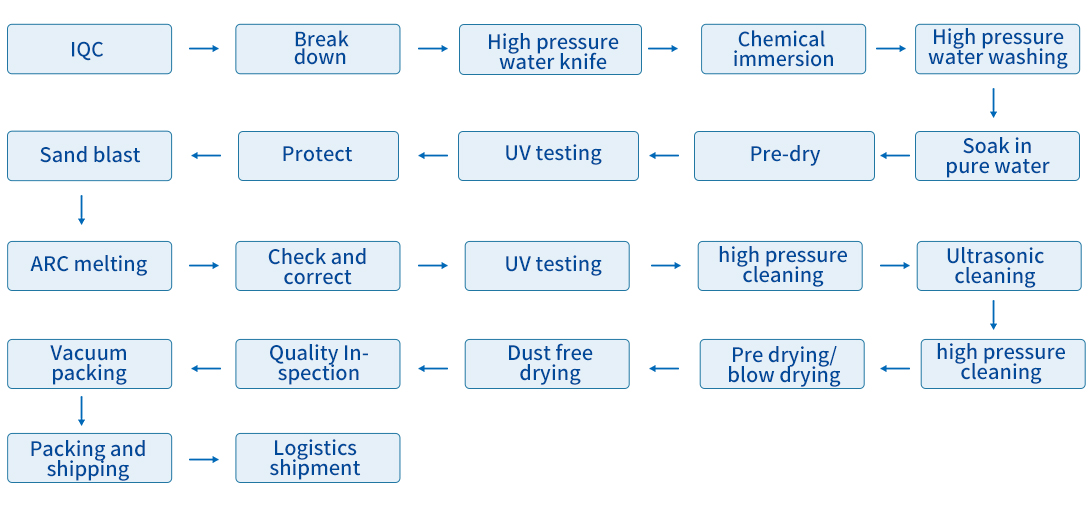

- DE wall panel oxidation regeneration process flow

- DE wall panel oxidation regeneration process

- Service History

- Open Mask Industry Solutions

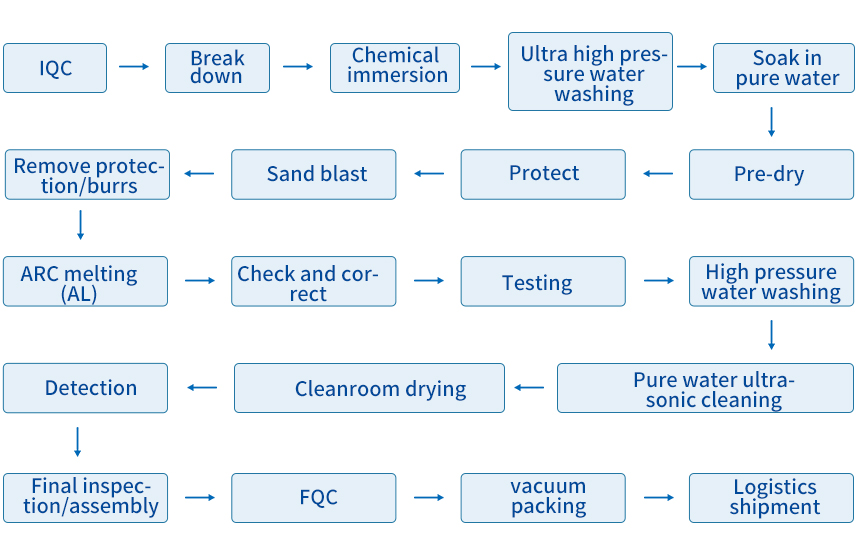

- Open Mask Operation process

- QC Flow Chart

- Open Mask Cleaning Process Flow

- Open Mask Cleaning specifications

- Cleaning specifications

- Semiconductor Industry Solutions

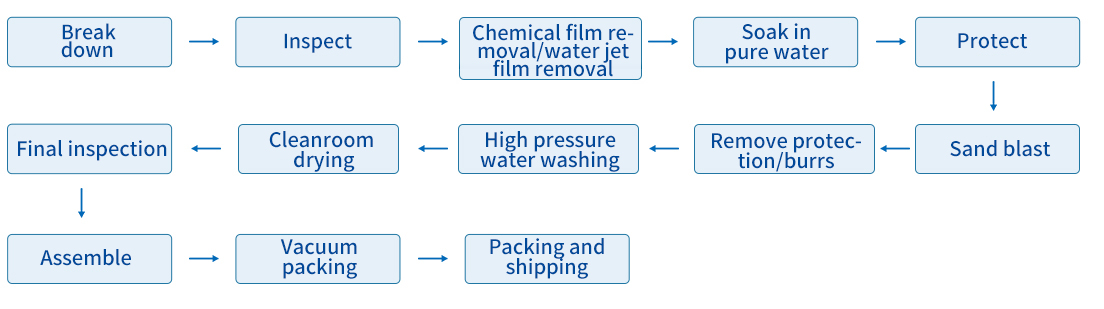

- Photovoltaic cleaning and regeneration process flow - carrier board

- Process flow of semiconductor component cleaning and regeneration

- Ceramic Melting Industry Solutions

- DE Ceramic Component Cleaning and Regeneration Process Flow

- DE Ceramic Component Cleaning Process

- Service History

- Surface treatment process flow of components

- Introduction to Ceramic Melting and Spraying

- Ceramic melting business

- Product Display (Optoelectronics)

- Product Display (Semiconductor)

- Product Display (Semiconductor ESC)

- Ceramic melting technology module

- Ceramic melt blown derivative process (stripping technology)

- Ceramic melt blown derivative process (new oxidation process)

- Surface treatment process flow of components

- Performance testing of oxidation new process performance indicators

- Ceramic melt blown derivative process (cleaning and regeneration process)

- Surface treatment process flow of components

- leaning and regeneration technology capability

- Special product (power on processing)

- Service History

- Cleaning industry Solutions

- PVD component cleaning and regeneration process flow

- Service History

- CF component cleaning and regeneration process flow

- IMP cleaning process flow

- Service History

- Process flow for cleaning and regenerating inner lining components

- Service History

- Quality control capability

- Cleaning and regeneration technology capability

- Advantages of advanced process precision cleaning

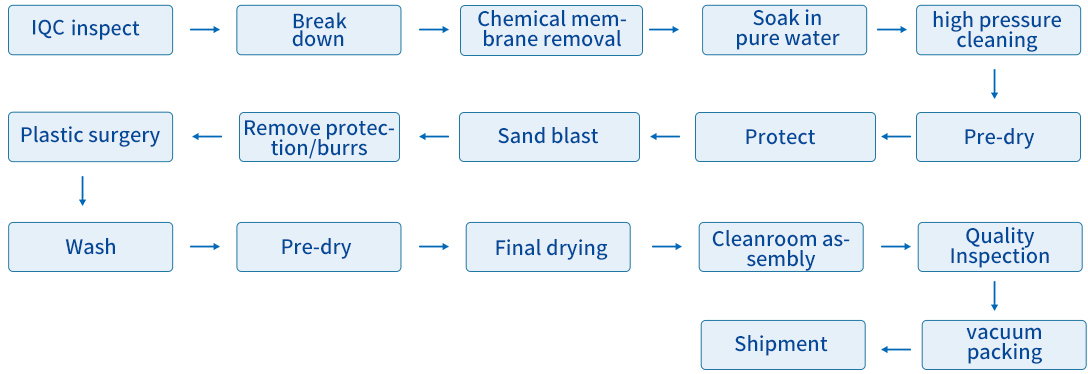

- Photovoltaic cleaning and regeneration process flow - carrier board

- CVD Industry Solutions

- CVD component cleaning and regeneration process flow - Diffuser

- CVD component cleaning and regeneration process flow - Baking Plate

- CVD component cleaning and regeneration process flow 1-Susceptor

- CVD component cleaning and regeneration process flow 2-Susceptor

- CVD component cleaning and regeneration process flow - Shadow Frame

- Core technology

- Service History

① IQC

Inspect appearance defects and provide feedback to customers, distinguish devices, film quality, materials, and prepare process flow forms.

② Break down

When cleaning the assembly, effectively clean the individual behind it.

③ Acid washing+ultra-high pressure water knife

Soak in nitric acid first to loosen the film layer on the component; Then, using physical methods, the components are rinsed with an ultra-high pressure water knife to remove the film layer. (ITO film and AL film are only treated with water jet).

④ Soak in pure water

After ultra-high pressure water washing, soak the surface residue of the parts in pure water to remove it.

⑤ Pre-dry

After soaking in pure water, pre drying is carried out to remove surface moisture, which is beneficial for the next process operation.

⑥ Protect

Parts that do not require sandblasting should be protected with tape or fixtures.

⑦ Sand blast

Under a certain process pressure, sandblasting is performed on the components to achieve the required roughness standard for film deposition.

⑧ Remove protection, burrs, check and correct

After sandblasting is completed, remove the protective fixtures and tape, remove burrs at the edges of the sandblasting, and correct any deformations or dimensional defects.

⑨ Detection

The parts are placed on a marble platform and the warpage is measured using a feeler gauge. If it is not within the standard range, it should be corrected to ensure that the flatness is qualified. The measurement data should be recorded on the checklist.

Measure the components with measuring tools according to the items specified in the checklist, and record the results on the checklist.

⑩ High pressure water washing

⑪ Dry

Rough cleaning of sandblasted parts under certain process pressure to remove surface particles.

⑫ ARCplasma spray

⑬ Data detection

⑭ High pressure water washing

According to the process parameters specified in the process flow sheet, set the parameters of the ARC meltblown machine and perform the melting operation. After the operation is completed, evaluate and measure the roughness of the melted coating to ensure that the measurement data meets the standard requirements. Then, proceed to the next process for high-pressure water washing to remove surface dust.

⑮ Cleanroom drying

Dry according to the process requirements.

⑯ Final inspection

Conduct a visual inspection to check for any appearance defects, and conduct relevant dimensional data checks based on the inspection checklist.

⑰ Assembling

⑱ FQC test

⑲Vacuum packing

Assemble components according to standard drawings, paying attention to the directionality of the components during assembly. After the assembly is completed, FQC will inspect and confirm the appearance and dimensional data.

Inner white and outer green vacuum packaging (two-layer).

⑳ OQC、Packing and shipping

According to the customer category, equipment, film quality, etc. on the process flow sheet, cushion material air cushion film is bundled and packed into boxes.

OQC prepares inspection reports and lists, and ships after packing is completed.

|

department |

product |

customer |

generations |

category |

equipment manufacturer |

|

PVD |

MASK |

Hefei BOE(B3) |

G6 |

LCD |

ULVAC |

|

Chongqing BOE(B8) |

G8.5 |

LCD |

ULVAC |

||

|

Hefei BOE(B9) |

G10.5 |

LCD |

ULVAC |

||

|

Chuzhou Huike |

G8.6 |

LCD |

AKT |

||

|

Chongqing Huike |

G8.6 |

LCD |

AKT |

||

|

Shanghai Tianma |

G4.5 |

LCD |

ULVAC |

||

|

Wuhan Tianma |

G4.5 |

LCD |

ULVAC |

||

|

Wuhan Tianma |

G6 |

OLED |

IRUJA |

||

|

Chengdu Tianma |

G4.5 |

LCD |

ULVAC |

||

|

Xiamen Tianma |

G5.5 |

LTPS |

ULVAC |

||

|

Xiamen Tianma |

G6 |

LTPS |

ULVAC |

||

|

AVIC |

G5 |

LCD |

ULVAC |

||

|

Soaring dragon |

G5 |

LCD |

ULVAC |

||

|

Nanjing panda |

G6 |

LCD |

ULVAC |

||

|

Nanjing panda |

G6 |

LCD |

AKT |

||

|

Huaxingguang T3 |

G6 |

LTPS |

ULVAC |

||

|

HuaxingguangT4 |

G6 |

OLED |

IRUJA |

||

|

Guoxian Optoelectronics |

G5.5 |

OLED |

ULVAC |

|

department |

product |

customer |

generations |

category |

equipment manufacturer |

|

PVD |

MASK |

Hefei BOE(B3) |

G6 |

LCD |

ULVAC |

|

Chongqing BOE(B8) |

G8.5 |

LCD |

ULVAC |

||

|

Hefei BOE(B9) |

G10.5 |

LCD |

ULVAC |

||

|

Chuzhou Huike |

G8.6 |

LCD |

AKT |

||

|

Chongqing Huike |

G8.6 |

LCD |

AKT |

||

|

Shanghai Tianma |

G4.5 |

LCD |

ULVAC |

||

|

Wuhan Tianma |

G4.5 |

LCD |

ULVAC |

||

|

Wuhan Tianma |

G6 |

OLED |

IRUJA |

||

|

Chengdu Tianma |

G4.5 |

LCD |

ULVAC |

||

|

Xiamen Tianma |

G5.5 |

LTPS |

ULVAC |

||

|

Xiamen Tianma |

G6 |

LTPS |

ULVAC |

||

|

AVIC |

G5 |

LCD |

ULVAC |

||

|

Soaring dragon |

G5 |

LCD |

ULVAC |

||

|

Nanjingpanda |

G6 |

LCD |

ULVAC |

||

|

Nanjingpanda |

G6 |

LCD |

AKT |

||

|

Huaxingguang T3 |

G6 |

LTPS |

ULVAC |

||

|

HuaxingguangT4 |

G6 |

OLED |

IRUJA |

||

|

Guoxian Optoelectronics |

G5.5 |

OLED |

ULVAC |

① Break down

Disassemble the components, classify them, and then clean them separately.

② IQC inspect

Visual defect inspection and feedback to customers, distinguishing film layers, materials, and production process flow sheet.

③ Chemical film removal/water jet film removal

Soak in nitric acid first to loosen the film layer on the component; Then, using physical methods, the components are rinsed with an ultra-high pressure water knife to remove the film layer. (Aluminum plate can be directly removed by water knife without chemical immersion).

④ Soak in pure water

After ultra-high pressure water washing, soak the surface residue of the parts in pure water to remove it.

⑤ Protect

Protect areas that do not require sandblasting with tape or fixtures.

⑥ Sand blast

Sandblasting the parts under a certain pressure (5-8kg/cm ²) and achieving the roughness standard, Ra=5-14um.

⑦ Remove protection, burrs/polishing

After sandblasting, remove the protective tape and fixture, and polish the smooth surface.

⑧ High pressure water washing

After sandblasting is completed, the parts are subjected to high-pressure water washing at a pressure of 50 bar to remove residual sand, dust, and particles.

⑨ Cleanroom drying

Final drying of components, drying requirement: 150 ° * 2H.

⑩ Inspect

Conduct a visual inspection for any defects or defects, and conduct relevant data checks to ensure flatness is controlled below 1mm.

⑪ Assemble

According to the requirements, clamp peek、 Assemble the upper and lower guide rails, pay attention to the direction of assembly.

⑫ vacuum packing

Vacuum package the parts with two layers of vacuum bags, and we can package them according to customer requirements in terms of color and number of layers.

⑬ Packing and shipping

OQC completes inspection report, list, and shipment after packing is completed.

① Input decomposition

Decompose the components, distinguish their appearance, quantity, and materials, and clean them using specialized processes.

② Liquid wash

Soak stainless steel anti sticking plate components in a new nitric acid solution for 0.5-1 hour.

MO material components soaked in diluted hydrofluoric acid tank for 3-15 seconds.

High pressure water washing to remove acid from components.

③ Pre-dry

Pre dry the components and prepare them for flow into the sandblasting section (note: the surface of the components should be free of moisture).

④ Sand blast

Sandblasting the surface of the component to improve its surface roughness (note: confirmation of air pressure is required before sandblasting).

⑤ Intermediate inspection

Surface polishing treatment of aluminum components.

⑥ Intermediate inspection

Confirm the flatness of the components on the marble platform, and correct any deformation if necessary.

Use professional instruments to randomly check the surface roughness of components, and flow qualified components into the next section.

⑦ Wash

Using ultrasonic equipment to remove surface micro particles.

Use an air gun to dry the surface of the component (note: there should be no water residue in each screw hole).

⑧ Heat drying

Place the components in the oven for final drying. (Note: Before opening the oven, confirm the temperature and time settings).

⑨ Assemble

Assemble each set of components according to their original state upon arrival (note: confirm the orientation of each set of components before tightening the screws).

⑩Quality Inspection

Check and confirm the appearance, flatness, assembly effect, surface roughness, etc. of the components.

⑪ Vacuum packing

Vacuum package the components that have passed the inspection to ensure that they do not come into contact with air.

⑫ Packing and shipping

Transport the components in a dedicated turnover box to ensure their safe transportation.

|

department |

product |

customer |

Customer Generation |

category |

|

IMP |

Electrode plate |

Hehui Optoelectronics |

G4.5 |

OLED |

|

Huaxing Optoelectronics (T4) |

G6 |

OLED |

||

|

Huaxing Optoelectronics (T3) |

G6 |

LTPS |

||

|

Xiamen Tianma |

G6 |

LTPS |

||

|

Wuhan Tianma |

G6 |

OLED |

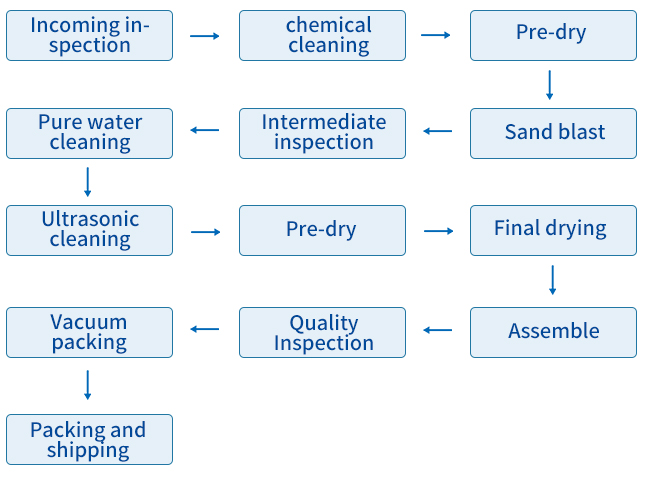

① IQC

② Break down

Inspect appearance defects and provide feedback to customers, distinguish devices, film quality, materials, and prepare process flow forms. When cleaning assembly parts, decompose them and effectively clean them individually.

③Soak in medicine+rinse with high-pressure water

Remove the film layer on the component by soaking it in a solution; Then, physical methods are used to rinse the components with high-pressure water to remove residual film layers.

④ Soak in pure water

Soak the surface residue of the parts in pure water after high-pressure water washing.

⑤ Pre-dry

After soaking in pure water, pre drying is carried out to remove surface moisture, which is beneficial for the next process operation.

⑥ Protect

Parts that do not require sandblasting should be protected with tape or fixtures.

⑦ Sand blast

Under a certain process pressure, sandblasting is performed on the components to achieve the required roughness standard for film deposition.

⑧ Remove protection/burrs

After sandblasting is completed, remove the protective fixtures and tape, remove burrs at the edges of the sandblasting, and correct any deformations or dimensional defects.

⑨ ARC plasma spray

Set the parameters of the ARC melting machine according to the process parameters specified in the process flow sheet and carry out the melting operation.

⑩ Data detection

Measure the components with measuring tools according to the items specified in the checklist, and record the results on the checklist.

⑪ High pressure water washing

Under certain process pressure, perform rough cleaning on sandblasted parts to remove surface particles.

⑫ Pure water ultrasonic cleaning

Use ultrasonic waves to remove micro particles on the surface of components.

⑬ UV lamp inspection

Check for organic residues on the surface of the component using a UV lamp.

⑭ Cleanroom drying

Dry according to the process requirements to ensure that there is no residual moisture on the surface of the components.

⑮ Final inspection

Conduct a visual inspection to check for any appearance defects, and conduct relevant dimensional data checks based on the inspection checklist.

⑯ FQC inspection

Inspect and confirm the appearance, flatness, roughness, and other aspects.

⑰ Vacuum packing

Two layer dust-free vacuum packaging.

⑱ Logistics shipment

According to the customer category, equipment, film quality, etc. on the process flow sheet, cushion material air cushion film is bundled and packed into boxes. OQC prepares inspection reports and lists, and ships after packing is completed.

|

Department |

Product |

Customer |

Generations |

Machine Table |

|

Vapor deposition |

Inner lining cleaning |

Hehui Optoelectronics |

G4.5 |

TOKKI |

|

CSOT |

G6(Experimental line) |

TOKKI |

||

|

Guoxian Optoelectronics |

G5.5 |

TOKKI |

||

|

Wuhan Tianma G6 |

G6 |

ULVAC/TOKKI |

||

|

Mianyang BOE B11 |

G6 |

TOKKI |

||

|

Open mask |

Wuhan Tianma G6 |

G6 |

ULVAC |

|

|

Chengdu BOE B7 |

G6 |

TOKKI |

||

|

Mianyang BOE B11 |

G6 |

TOKKI |

① Incoming inspection, input into the system:

Based on the main material of the parts (AL base material, SUS material) and the type of film, the cleaning process is selected. Colleagues calculate the cleaning times of the parts according to the engraved numbers, and the company designs a list form for internal use, which can efficiently and quickly distinguish parts.

② Homework control system:

A. Film removal standard: Parts are treated by physical or chemical means to clean the residual film on the surface of the parts, and the frequency and frequency of drug use are controlled.

B. Shielding standard: Use tape or fixtures to protect non treated surfaces of parts without gaps, and control the drawings.

C. Sandblasting parts standard: uniform appearance color, no color difference, no residual film, roughness meets requirements, and roughness SPEC is controlled.

D. Standard for fused parts: no color difference, no scratches, no marks, no black spots, etc; The roughness meets the requirements and the roughness SPEC is controlled.

③ Standard control after intermediate inspection:

A. Plastic surgery standard: Parts are physically corrected to achieve SPEC size.

B. The roughness meets the requirements and the roughness SPEC is controlled.

④Standard control after cleanroom operation:

The number of particles (ea/cm2) on the surface of the tested components meets the product shipment inspection SPEC.

⑤ Control of Packaging and Shipping Inspection Standards

Check and confirm the quantity of parts, stickers, and vacuum packaging, and conduct overall final confirmation of the parts before shipment.

⑥ Data statistics system

Record cleaning component data, update component cleaning history, establish component cleaning big data, and provide customers with more reasonable and reliable SPEC references.

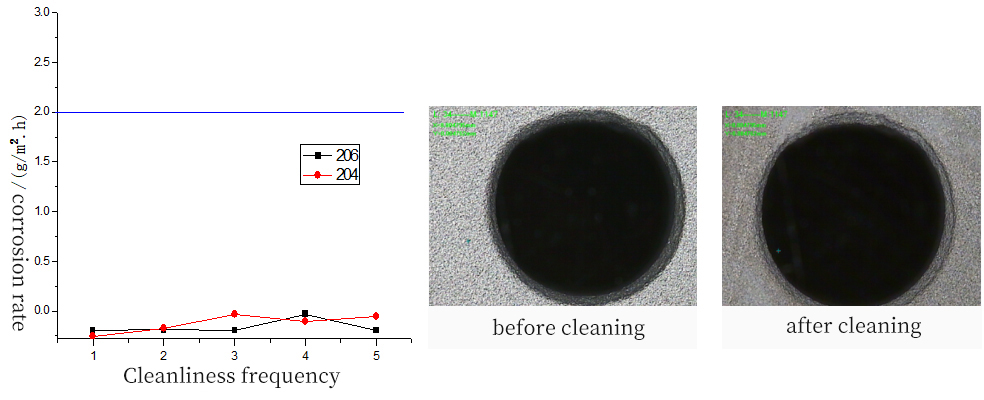

A. Unique cleaning agent formula, maximizing control of component corrosion issues and increasing customer usage frequency.

After 5 cleaning cycles, the porous aluminum alloy part showed almost no increase in corrosion of the micropores, and the micro corrosion data was stable during each cleaning cycle, indicating that this technology can stably and controllably clean and regenerate the components.

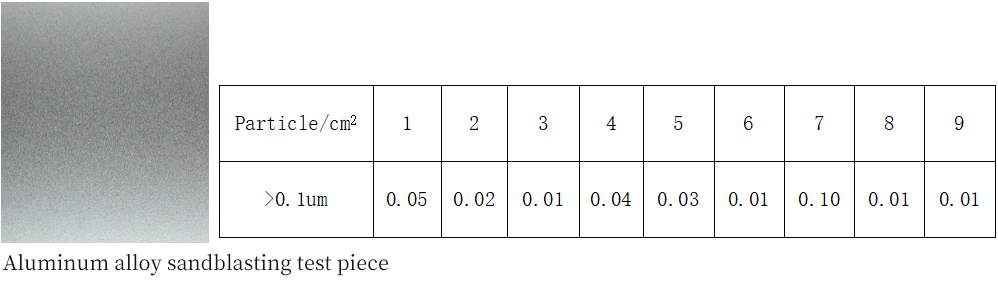

B. Strictly control the cleaning and cleanroom environment to ensure that the particle level on the surface of the components meets the customer's requirements for installation.

After precise cleaning, the test piece is subjected to ultrasonic waves and dried in a clean room to test the particle level

Fully meet the particle level requirements of all precision cleaned parts currently available

C. After cleaning, strictly control the residual level of metal ions on the surface of the components to prevent contamination by metal ions.

| 1E10Atoms/cm2 | Li | Na | Mg | Al | K | Ca | Ti | V | Cr | Mn | Fe | Co | Ni | Cu | Zn | Ge | Y | Zr | Mo | W | Pb |

| SPEC | 60.00 | 200.00 | 50.00 | 600.00 | 200.00 | 95.00 | 60.00 | 30.00 | 50.00 | 30.00 | 70.00 | 30.00 | 50.00 | 50.00 | 50.00 | 30.00 | 30.00 | 30.00 | 30.00 | 30.00 | 30.00 |

| Test piece | 0.01 | 2.52 | 0.50 | 30.93 | 0.69 | 2.93 | 6.44 | 0.01 | 0.08 | 0.04 | 8.75 | 0.05 | 0.09 | 0.80 | 3.79 | * | * | * | 0.08 | 0.02 | * |

After precision cleaning, test the residual level of metal ions on the surface of the test piece after drying.

Fully meet the current requirements for metal ion residue levels in all precision cleaned parts.

Quality control:

☆ Realize online monitoring of cleanroom cleanliness, temperature and humidity.

☆ Realize online monitoring of pure water.

☆ Implement SPC control for key parts.

☆ Fully introduce fixtures to achieve fixture based masking and measurement, reducing human impact.

☆ Introduce more automated work equipment.

1. IQC inspection

Inspect the appearance of the carrier board for defects and missing components, and create a contact letter for receiving defects.

Record the engraved numbers of each component on the carrier board at the corresponding positions on the drawing for assembly in the clean room.

2. Decomposition

According to the requirements of the disassembly operation manual, decompose the carrier board and print the engineering list to complete the incoming work.

3. Chemical membrane removal

Potions: HNO3:H2O=1: 1. Condition: 45 ± 5 ℃ × (3~4H), remove the facial mask layer on the surface of the component; When soaking in the solution, pay attention to separating each product to prevent the residue of the film layer caused by the solution not soaking in the overlapping position.

4. Soak in pure water

Soak in pure water overflow for 10 minutes to remove residual surface chemicals.

5. High pressure water washing

High pressure water gun should be used to flush the residual film on the surface. Remember to adjust the water gun to the appropriate pressure to prevent product deformation during flushing (the positioning hole must be cleaned thoroughly).

6. Drying

Drying: After blowing the moisture on the surface of the pocket with an air gun, dry it at 90 ° C for 30 minutes.

7. Protection

Screw protection is required for the screw holes on the crossbeam and vertical beam positions, as well as for the smooth surface tape protection and assembly overlap positions; Use fixtures to protect the smooth surface of the pocket and strictly protect the circular positioning holes. (Positioning holes and pin holes need to be protected with screws and washers).

8. Sandblasting

Place the protected product on the sandblasting table for sandblasting operations; Pocket sandblasting attention conditions: WA80 # × (3-4 kg/cm2) Ra=Ra2.0- Ra3.2 μ m.

9. Remove protection/burrs

Remove the protection of sandblasting, polish the smooth surface (with no residual film or sand), and remove burrs from the blade position.

10. Plastic surgery

Correction: Place the parts on a marble platform for correction: the flatness of the left and right vertical beams is less than 1mm, the flatness of the horizontal beam is less than 0.5mm, and the flatness of the pocket is less than 0.15mm.

11. High pressure water washing/ultrasonic cleaning

Both sides need to be rinsed, with a high-pressure water gun pressure of 50par (the pocket should be placed horizontally during rinsing). Ultrasonic cleaning 1200W for 10 minutes.

12. Pre drying

Pre dry the cleaned components at 90 ° for 30 minutes.

13. Final drying

The components are finally dried in a clean room at 150 ° C for 2 hours. After drying, they are naturally cooled to room temperature to confirm the flatness of the components before assembly, ensuring that the appearance and flatness are qualified.

14. Assembly

According to the received drawing, locate the components with a group of engraved numbers, and install each component corresponding to the drawing (assembly sequence: first assemble the crossbeam and vertical beam (diagonal<2cm), then adjust the position of the pocket, install the pin, pad the pocket with an equal height block, install all screws, adjust the gap around the pocket, lock the side screws, and finally lock the pocket screws).

15. Final inspection

Inspect components according to inspection standards and measure relevant data; And produce a shipment report based on the measurement data.

16. Vacuum packaging

Packaging requirements: double-layer packaging, one layer of vacuum, and one layer of anti-static.

17. Packing and shipping

OQC completes the inspection report, checklist, and confirms that there are no omissions. The box is packed and wrapped with dust-free film, and labels are printed before shipment.